Facts About Mhs - Material Handling Supply Inc. Revealed

Facts About Mhs - Material Handling Supply Inc. Revealed

Blog Article

The Definitive Guide to Mhs - Material Handling Supply Inc.

Table of ContentsThe Ultimate Guide To Mhs - Material Handling Supply Inc.The Buzz on Mhs - Material Handling Supply Inc.Not known Factual Statements About Mhs - Material Handling Supply Inc. The 10-Minute Rule for Mhs - Material Handling Supply Inc.Fascination About Mhs - Material Handling Supply Inc.The 10-Minute Rule for Mhs - Material Handling Supply Inc.Mhs - Material Handling Supply Inc. - Truths

As a whole, this devices is most frequently made use of in an industrial setting to relocate items and products. There are 4 significant sorts of material handling equipment that aid stockrooms and factories move and keep goods, which are: Transport Devices Positioning Equipment Unit Lots Development Equipment Storage space Equipment Industrial vehicles, like forklifts, autumn under product handling tools and are used to relocate hefty materials safely.

As the name indicates, you can take a seat when running a sit-down rider. Contrasted to standing making use of a stand-up cyclist. Furthermore, sit-down motorcyclists are understood for relocating at rapid rates. Especially when lifting and lowering. Hence, operating at a high volume. Rough surface forklifts are constructed to operate at building websites or various other places on unequal surface areas.

Unknown Facts About Mhs - Material Handling Supply Inc.

When it pertains to material handling forklifts, telehandlers can get to the greatest elevations and bring the most weight - forklift rental athens, ga. With a slim aisle forklift, you can do more with less space. Slim aisle forklift vehicles are made to be made use of in aisles that measure less than 10 feet by 12 feet

An is a sort of material handling equipment used to choose and supply goods from storage space for orders. Order pickers allow drivers easily and rapidly choose items from bins of various SKUs for order gratification. are the easiest form of forklift and are used to relocate pallets in storage facilities.

An additionally known as a, is a motorized forklift utilized to help building and construction employees in reaching high altitudes for work and projects. There are a number of different kinds of airborne lifts that are designed for different building tasks which we have actually provided below.

Top Guidelines Of Mhs - Material Handling Supply Inc.

Utilizing them, business workers can get to elevated heights or hard-to-reach areas comfortably. Since there are many kinds of boom raises, it's vital to find out the different attributes and features of each.

These cars lift individuals into the air securely in order to carry out jobs. are aerial lifts designed to function in extremely limited and restricted rooms. The combination of high lifts, reach, and flexibility of these systems makes them a secure solution. These vertical pole raises feature wheels, hence making it simple to relocate and move the lightweight equipment.

How Mhs - Material Handling Supply Inc. can Save You Time, Stress, and Money.

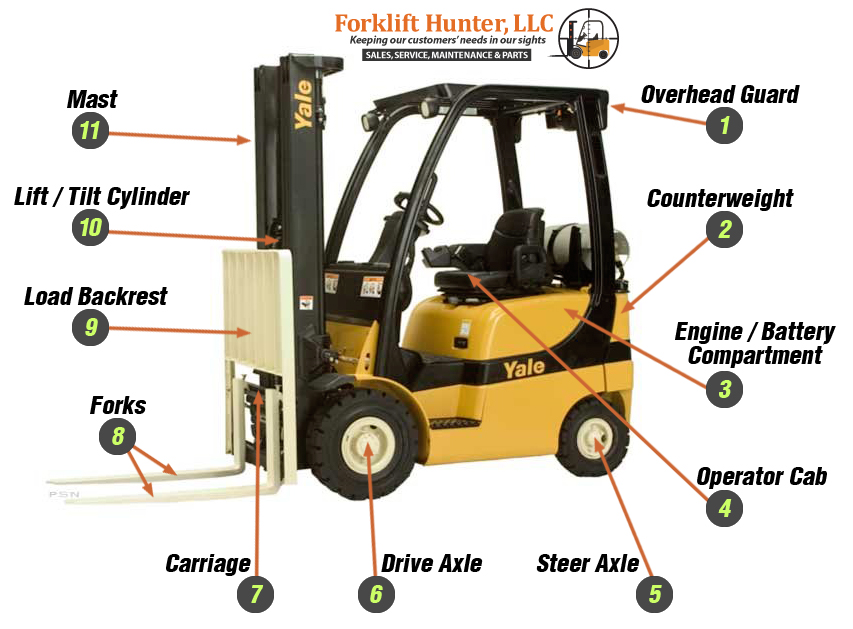

It is being extensively utilized throughout the sector for transporting materials and goods. Forklift includes variety of components needed to manage the job efficiently. From Truck Frame, source of power to counterweight are necessary for the forklift to operate successfully. Vehicle Frame is the most important element which develops the base of the device.

The Weight is a cast iron weight connected to the back component of the forklift. The aim of the counterweight is to counter balance the tons that is being lifted. On Electric Forklift, Weight is dealt with to the lead-acid battery. The forklift's source of power contains an interior combustion engine.

The carriage serves as the base to the forklift. The Pole is an upright component that raises up and pushes down the loads.

The Of Mhs - Material Handling Supply Inc.

Air gets allured through the base of the cylinder that permits gasses to get in without leaking them out. This force creates the piston to relocate up, raising the volume of the gas and minimizing the stress.

The Operator pushes the handle in an ahead direction, signaling the forklift to pump excess air to the cylinders. The operator pulls the handle in backward instructions that indicates a special shutoff to discharge gas from cyndrical tubes. The hydraulic pistons are affixed to both primary vertical structures understood as "poles".

When the hydraulic pistons press the poles in higher direction, the gears on the masts is pushed against the roller chains. It takes place due to the fact that the one side of the chain is dealt with to the immovable frame of the forklift, and the only way whereby poles can move upward is when gears turn in clockwise instructions and draw the forks expenses.

Examine This Report on Mhs - Material Handling Supply Inc.

There are two pairs of additional hydraulic cyndrical tubes connected to the base of the poles. When the Tilt Deal with is relocated in ahead instructions, the air automatically fills the chamber (Forklift dealer). The increase in stress is enough to press the head of the piston and let the poles quit the car's body

The Buzz on Mhs - Material Handling Supply Inc.

When the pistons are pressed forward, the masts are pressed back to the automobile. Forklifts have actually entirely transformed the storage and shipping markets. Forklifts were initial designed during very early component of the 20th century and currently had ended up being an important part of the modern-day industrial world. Forklifts are named after their fork-like prongs that raise up the load.

Report this page